Why This Matters Now?

Supply chain disruptions, inflation, consumer demand volatility, and rising costs of holding inventory are squeezing margins. E-commerce players are under pressure to forecast demand better, reduce waste, and improve order fulfillment accuracy. Agentic AI is being positioned as a lever to do all three.

Context & Big Picture

Recent weeks have seen multiple developments across research, enterprise pilots, and market adoption that together signal agentic AI is maturing fast in inventory optimization + order prediction. The gap between proof‐of‐concept and production use is narrowing.

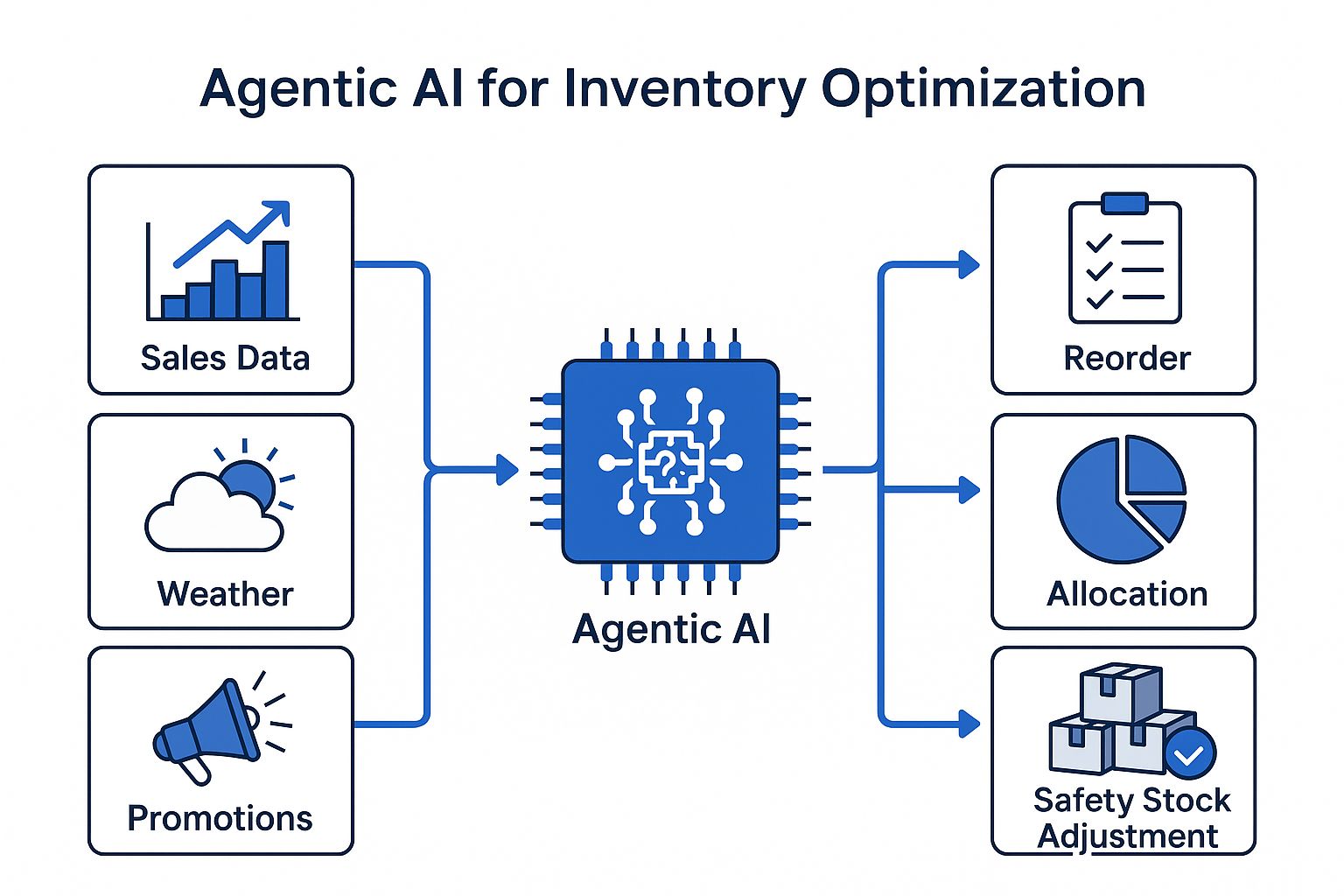

Broader trend: From reactive supply chains (responding to demand after the fact) toward autonomous, adaptive, predictive systems. Agentic systems (LLM-based or multi-agent systems) are combining various data streams (historical sales, external indicators, real‐time signals) and acting on forecasts (orders, replenishment, allocation) without human in the loop (or with minimal oversight).

Here’s what’s new & transformative:

A recently published benchmark called AIM-Bench (Aug 2025) has exposed decision-making biases of agentic LLM agents when used as inventory managers. Among other findings, agents display framing effects, “pull-to-centre” behavior, and are vulnerable to the bullwhip effect unless mitigated by information sharing or cognitive reflection.

Another new paper, Structure-Informed Deep Reinforcement Learning for Inventory Management, shows that DRL approaches, especially when informed by structural properties of optimal policies, can outperform classic heuristics/reservoir models in settings of perishable goods, multi-period ordering with lost sales, lead times, etc.

Recent enterprise piloting: Leading retailers (names are often confidential) are using agentic AI to reduce stockouts, lower inventory carrying cost, and dynamically adjust order quantities across store networks using real-time inputs (weather, promotions, competitor activity). These aren’t theoretical—they are real improvements in KPIs.

Why it matters in simple terms: Think of historical demand forecasting like looking in a rearview mirror and driving forward. Agentic AI is like installing full 360° radar + autopilot — it detects upcoming curves, adapts speed, and steers preemptively.

Technical Notes

Here are the key models, metrics, datasets, and algorithmic insights driving these breakthroughs:

Aspect | Details |

|---|---|

Benchmark / Biases | AIM-Bench, measuring LLM agents’ decision behavior in uncertain inventory replenishment settings. Metrics include bias effects (framing, pull-to-centre), bullwhip measure, cost of overstock vs stockout. |

DRL Advances | Structure-Informed DRL using DirectBackprop, dual sourcing, lead time, perishability. Learns policies across product classes, uses structural constraints so learning is more stable & interpretable. |

Enterprise Pilots | Real-time input streams like sales, weather, promotions; store network optimization; dynamic reorder points; automated replenishment agents; high forecast accuracy (sometimes >90%) in certain retail pilots. |

Datasets | Historical demand + sales per SKU; external features: weather, social media / sentiment, promotional calendar, lead times; also multi-location (store/warehouse), multi-product. Some public datasets in the DRL paper approximate lost sales under varying demand. |

Algorithms / Tools | Agentic LLM agents (using planning, memory, tool usage), DRL networks, hybrid models combining heuristics and learning; also digital twins + optimization solvers in some supply chain systems. |

Actionable Business Insights

What enterprises, e-commerce execs & operations teams need to know (and do) now:

Opportunities

Reduce inventory costs by dynamically adjusting safety stock, reorder points, and safety buffers using agentic agents rather than static rules. Small % improvements here scale up massively in cost saved and cash freed.

Improve service levels & reduce stockouts – particularly for fast movers or promotional items where demand swings rapidly. Forecasting errors there cost customer churn and margin.

Better order prediction for multi-warehouse networks: knowing where orders will come from allows pre-positioning, reduces shipping cost, fulfillment time.

Risk mitigation: with agentic agents that monitor supply disruptions, weather, lead time variance etc., you can proactively adjust procurement & inventory allocation.

Risks / Challenges

Biases & over-optimism from agentic LLMs: without checks, agents might under-estimate variance or be seduced by average trends (pull-to-centre), ignoring tail risk.

Data quality & infrastructure: many companies still don’t have timely, clean, granular data from all relevant streams (store-level, lead times, external indicators).

Explainability & trust: operations teams may resist agentic decisions if they can’t audit or understand why certain recommendations are made.

Governance & operational risk: agents with autonomy need guardrails (limits, human oversight).

So what? What to prioritize

Assess your data pipeline: do you have real-time sales, multi-region, external signal integration? If not, build or partner to fill gaps.

Start small pilots with agentic agents in a constrained product segment (fast movers, high cost of stockout or overstock). Measure improvements in forecast error, inventory turns, stockout events.

Incorporate bias detection / mitigation (e.g., AIM-Bench style) early: set up experiments to compare agent vs human/legacy, to detect framing or bias effects.

Build cross-functional teams (ops + data engineering + AI) and establish governance: define acceptable risk, thresholds, human override.

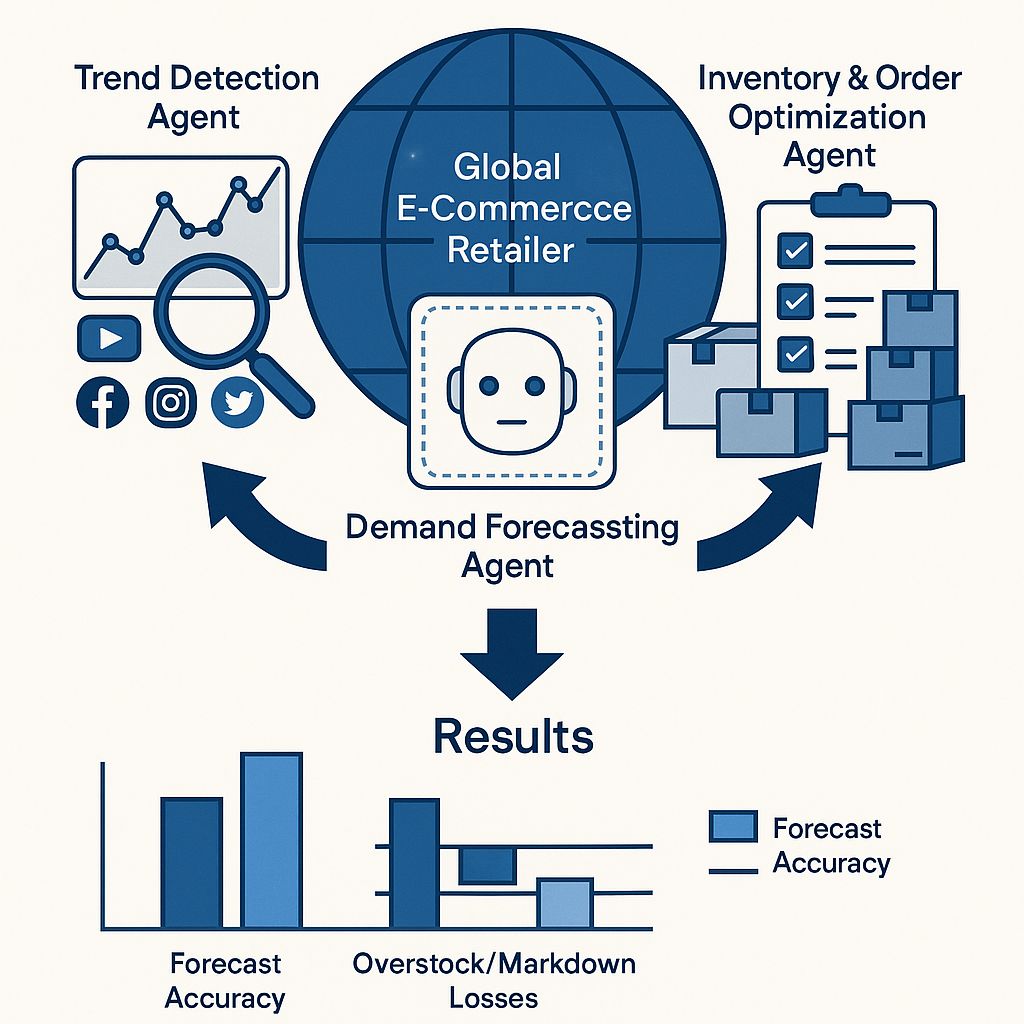

Case Study Deep Dive: How a Global E-Commerce Retailer Slashed Inventory Costs by 20% with Agentic AI

Background

A global fast-fashion e-commerce retailer (serving over 40 countries, 100M+ SKUs annually) was struggling with two persistent problems:

Overstock on seasonal items → leading to markdowns, waste, and storage cost.

Stockouts on trending products → leading to lost sales, unhappy customers, and churn.

Traditional forecasting models (ARIMA, Prophet, heuristic reorder rules) could only analyze historical sales data. But in a world where TikTok trends and Instagram Reels could spike product demand overnight, the models were always late to the party.

Solution: Deploying Agentic AI for Forecasting & Inventory Optimization

The retailer partnered with an AI vendor to implement a multi-agent system designed specifically for inventory optimization + order prediction.

The deployment included three specialized agents:

Trend Detection Agent 📈

Scraped social media platforms, Google Trends, influencer content, and search volumes.

Identified early signals of trend surges for specific SKUs (e.g., viral dresses, sneakers).

Demand Forecasting Agent 🤖

Combined historical sales, seasonality, promotions, weather, and trend signals.

Used Structure-Informed Deep Reinforcement Learning to forecast demand under uncertainty.

Adjusted dynamically for perishable and seasonal SKUs.

Inventory & Order Optimization Agent 📦

Simulated multiple replenishment policies using a digital twin of the retailer’s supply chain.

Recommended order quantities per warehouse.

Automated replenishment for top-selling SKUs (with human override for exceptions).

Implementation Timeline

Phase | Timeline | Key Actions |

|---|---|---|

Pilot | 3 months | Tested system on 200 SKUs across 2 markets. Measured forecast error, stockout rate, markdown % vs baseline. |

Scale-up | 6 months | Expanded to 5,000 SKUs, 12 warehouses, integrated with ERP + order management system. |

Full Rollout | 12 months | Deployed across all SKUs globally; added bias monitoring (AIM-Bench framework) to reduce pull-to-centre errors. |

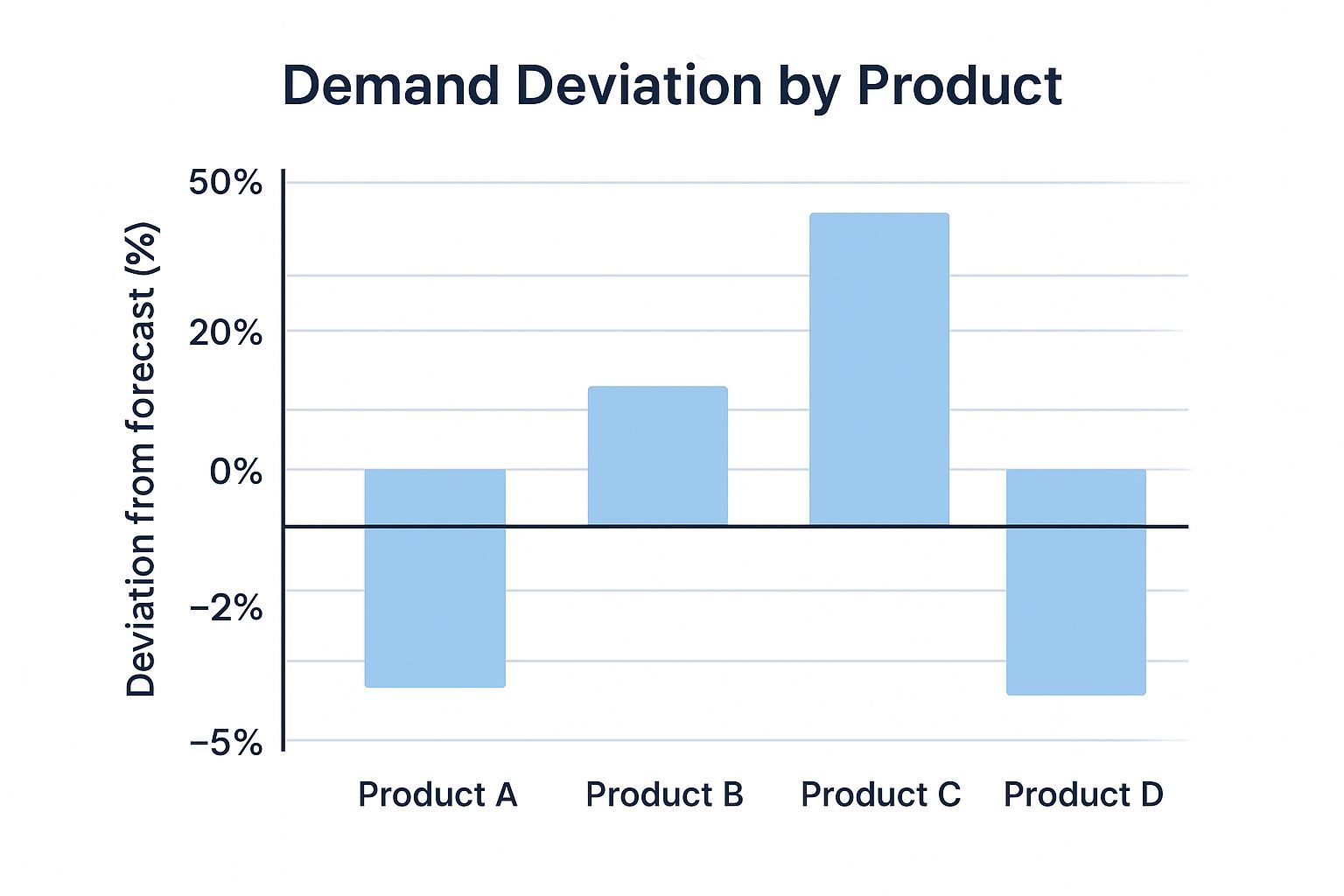

Results

The retailer saw dramatic improvements within the first year:

Forecast Accuracy: ↑ from 70% → 92% (measured via MAPE on SKU-level demand).

Stockouts: ↓ by 35%, leading to higher customer satisfaction scores.

Overstock / Markdown Losses: ↓ by 20%, freeing up working capital.

Inventory Holding Costs: ↓ by 18% due to leaner stock.

Revenue Impact: Estimated additional $120M in recovered sales (avoided lost sales + reduced waste).

Challenges & Lessons Learned

Data Gaps: Needed better granularity in SKU-level promotions data. Solution: integrated promotional calendars into AI pipeline.

Bias Mitigation: Early prototypes underestimated demand spikes (pull-to-centre bias). Solved by incorporating bias-aware training from AIM-Bench.

Change Management: Warehouse staff initially resisted “machine recommendations.” Conducted training workshops and set up explainability dashboards.

Strategic Takeaway

For this retailer, AI didn’t just cut costs — it enabled faster fashion cycles, better customer satisfaction, and real-time agility in responding to viral trends.

This case proves that demand forecasting + inventory optimization with agentic AI is no longer experimental. It’s a boardroom-level initiative that directly drives growth, resilience, and profit.

Closing Thoughts

The world is shifting from static forecasts and rigid rules to autonomous, adaptive intelligence. For e-commerce businesses, order prediction and inventory optimization are no longer back-office efficiency levers — they’re front-line strategic differentiators.

If you don’t build agentic forecasting & inventory systems now, your competitors who do will be able to lower cost, improve customer satisfaction, and respond faster to disruptions.